Material Stability in Durable ESD Floor Tiles Engineered for Long-Term Static Protection

Durable ESD Floor Tiles maintain long-term performance largely because of the stability of their conductive matrix. In homogenized PVC systems, the conductive additives disperse evenly throughout the tile rather than resting on the surface. This prevents conductivity loss caused by surface abrasion. When evaluating ESD Floor Tiles for industrial use, facilities often test volume resistivity changes after abrasion cycles, chemical exposure, and mechanical compression, ensuring that the flooring still falls within the required static-control resistance range even after years of wear.

Environmental Conditions That Influence the Lifespan of Anti Static Flooring Tiles

Humidity, airborne contaminants, and temperature fluctuations all influence the stability of Anti Static Flooring Tiles. For example, extremely low humidity accelerates static generation, increasing the load on the conductive network within the flooring. Cleanroom operators sometimes monitor humidity levels and use grounding pathways to maintain consistent static dissipation. Facilities producing microelectronics often use flooring systems with reinforced conductive layers to reduce performance fluctuations during seasonal environmental shifts.

Comparing Conductive Patterns Used in ESD Flooring Tiles

Different conductive pattern technologies affect how ESD Flooring Tiles behave under continuous industrial activity. Homogeneous conductive flooring distributes carbon particles throughout the tile body, while layered conductive flooring embeds a conductive grid under the surface. Homogeneous floors remain stable as the surface wears, whereas grid-based systems require controlled surface integrity to maintain conductivity. Anhui Hanhua Building Materials Technology Co., Ltd. supplies homogeneous conductive PVC tiles specifically for long-term static control in semiconductor and microelectronics facilities.

| Conductive Structure | Performance Impact | Best Application |

| Homogeneous Conductive | Stable after long-term abrasion | High-wear electronics lines |

| Layered Conductive Grid | Consistent surface conductivity when intact | Cleanrooms with controlled movement |

Chemical Resistance Considerations for Anti Static Floor Tiles in Industrial Spaces

Anti Static Floor Tiles installed in electronics and semiconductor plants must withstand flux residues, cleaning agents, and solvent vapors. Conductive PVC materials generally resist mild acids, alcohols, and common disinfectants. However, alkaline detergents may affect long-term gloss or microstructure. Facilities often create a compatibility chart comparing approved cleaning agents to maintain both the visual appearance and conductive stability of the flooring system over multiple years of use.

Maintenance Practices That Improve Durability of ESD Floor Tiles

Even though ESD Floor Tiles offer permanent conductivity, their durability depends on controlled maintenance routines. Using soft-bristle mechanical scrubbers, non-alkaline detergents, and scheduled particulate removal helps maintain grounding efficiency. In high-traffic zones, facilities often measure resistance to ground periodically and document changes in flooring performance. Anhui Hanhua’s products are used in facilities that follow strict maintenance logs to ensure stable static protection throughout the flooring’s lifecycle.

- Use cleaners within the recommended pH range to avoid degrading conductive paths.

- Avoid wax coatings that block conductivity in Anti Static Flooring Tiles.

- Perform periodic resistance testing using calibrated meters for long-term quality control.

Load-Bearing and Compression Behavior in Anti Static Floor Tiles

Facilities using heavy equipment, rolling carts, or pallet transport often examine compression recovery values of Anti Static Floor Tiles. A flooring system with poor recovery may deform under high pressure, creating uneven grounding pathways. Conductive PVC systems manufactured through homogenized compression typically show low deformation values, maintaining consistent contact between the tile surface and grounding systems. This is especially important in SMT, chip packaging, and assembly-line environments where movement of carts generates continuous static.

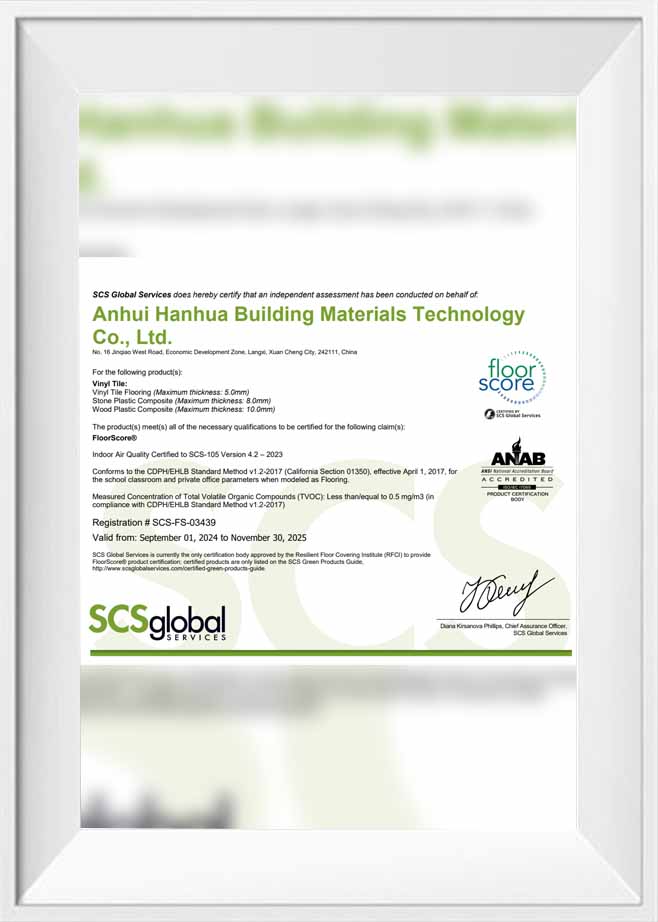

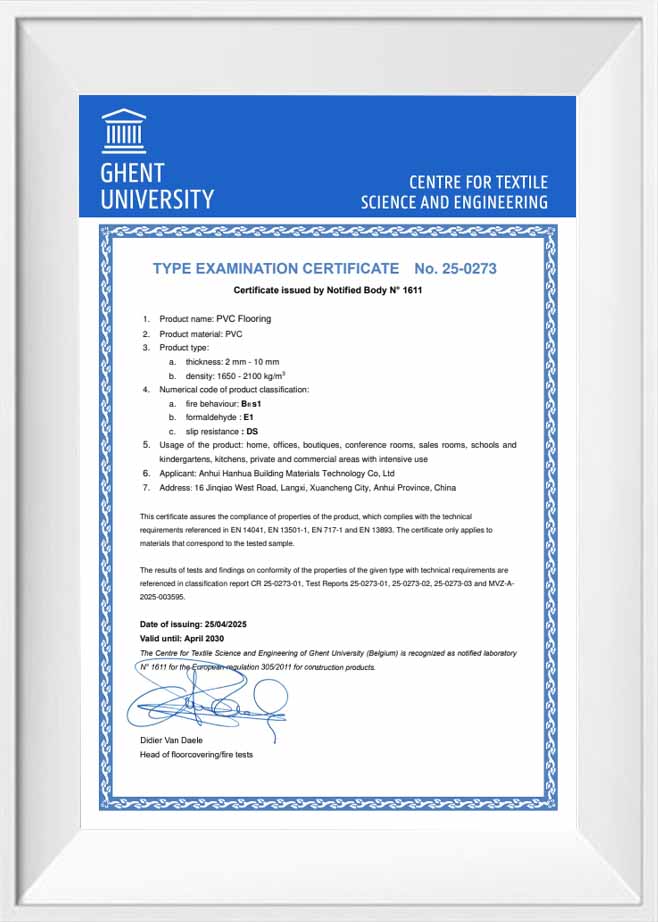

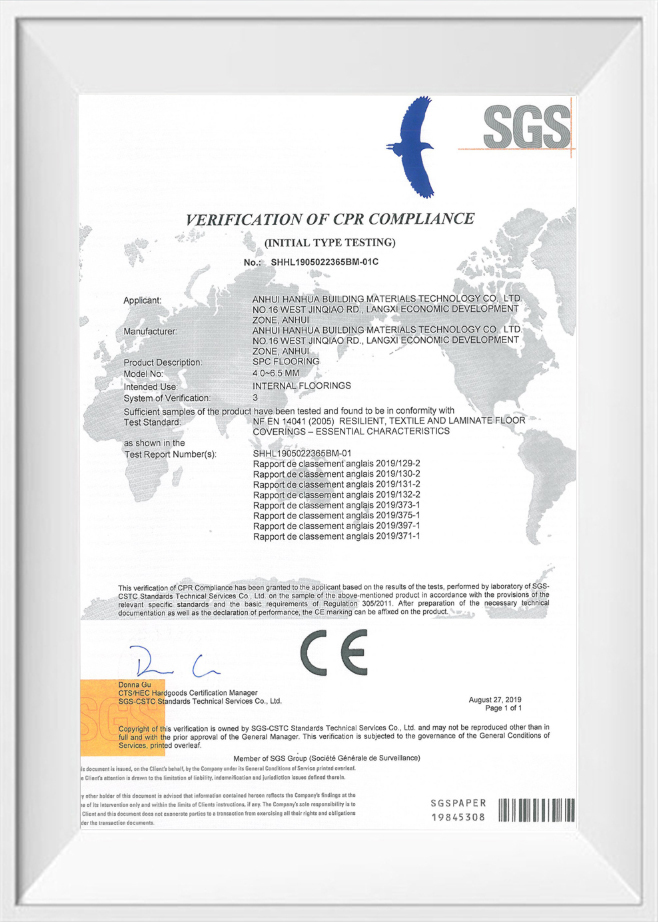

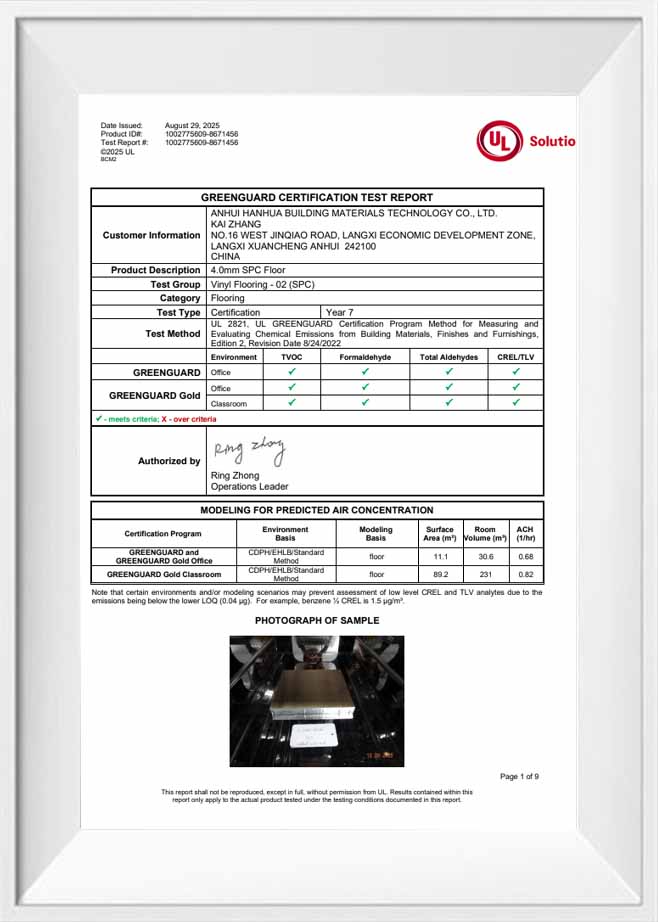

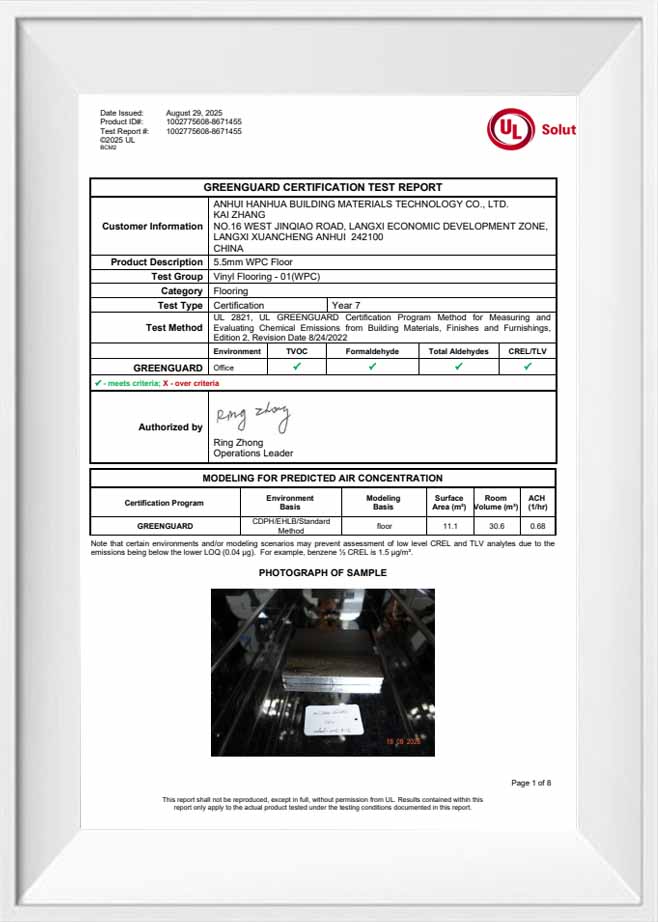

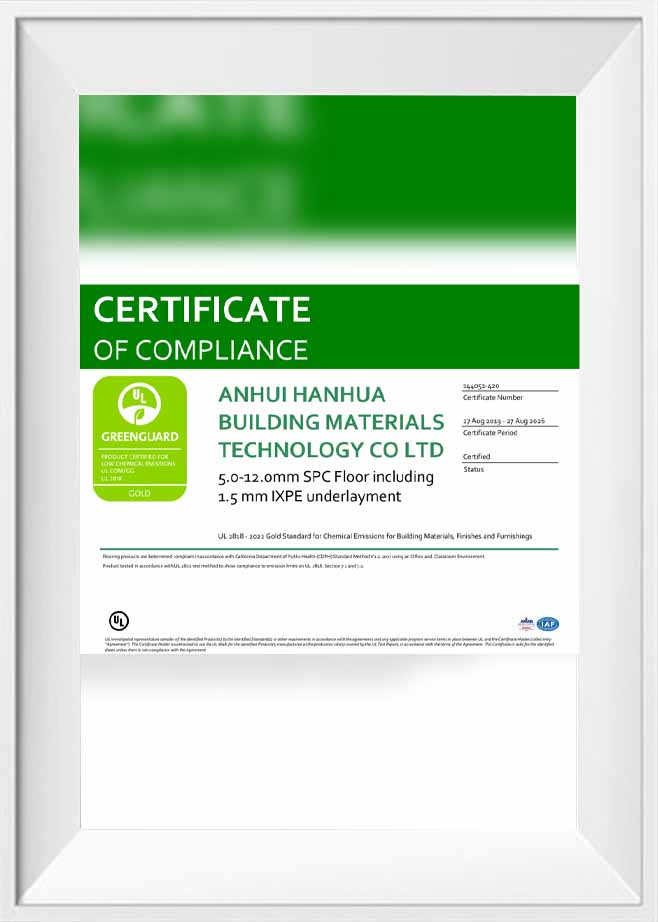

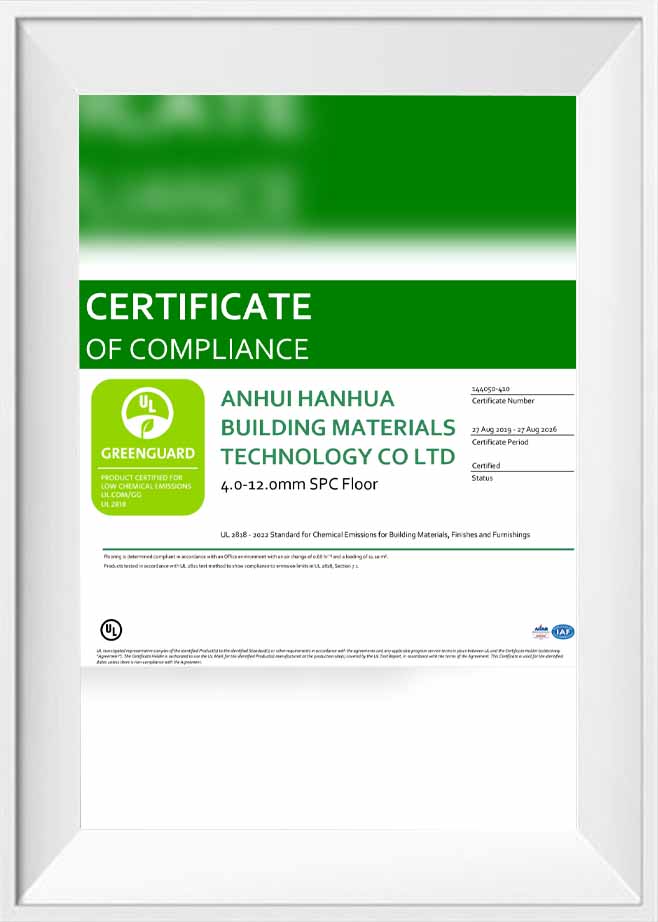

Export-Grade Certifications and Their Impact on Selecting Durable ESD Flooring Tiles

Many large-scale facilities prefer ESD Flooring Tiles that meet stringent international environmental and safety certifications. FloorScore and GreenGuard certifications indicate low VOC emissions, essential for closed production spaces where contaminants affect sensitive components. CE certification helps ensure compliance with EU static-control requirements. Anhui Hanhua Building Materials Technology Co., Ltd., which exports extensively to the United States, Australia, and Europe, develops conductive flooring that aligns with these global benchmarks to support professional procurement and long-term durability expectations.

English

English Español

Español Deutsch

Deutsch