Why Certification Matters for Flooring Accessories

Beyond aesthetics and fit, certified materials reduce hidden risks that directly affect indoor air quality and occupant health. Flooring Accessories such as transition strips, baseboards, thresholds, and edge trims often use adhesives, surface coatings or composite cores that can emit volatile organic compounds (VOCs). Choosing products with recognized certifications helps limit VOC emissions, prevents long-term off-gassing, and simplifies compliance when Flooring Accessories are installed alongside SPC, WPC, LVT or MGO systems.

Key Certifications and What They Control

Not all certifications target the same hazards. Understanding each certification’s scope enables specifiers to match Flooring Accessories to project health goals, especially in sensitive environments like schools, healthcare, and high-end commercial spaces.

| Certification | Primary Focus | Typical Limits / Tests | Relevance to Flooring Accessories |

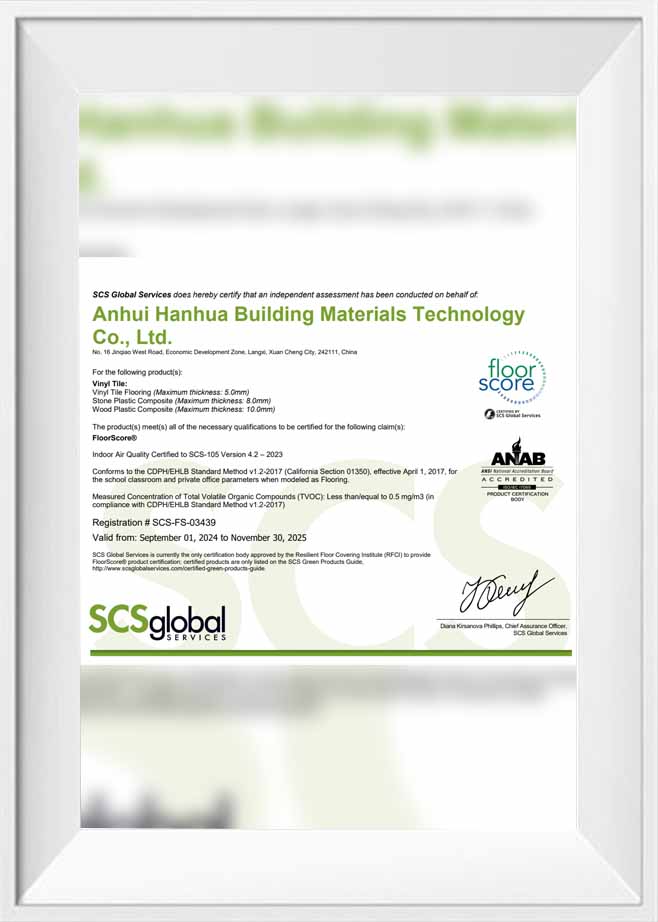

| FloorScore® | Indoor air quality — VOC emissions | Chamber testing for total VOCs and specific compounds (µg/m³ thresholds) | Ensures trims, profiles and adhesives won’t push room concentrations over safe levels. |

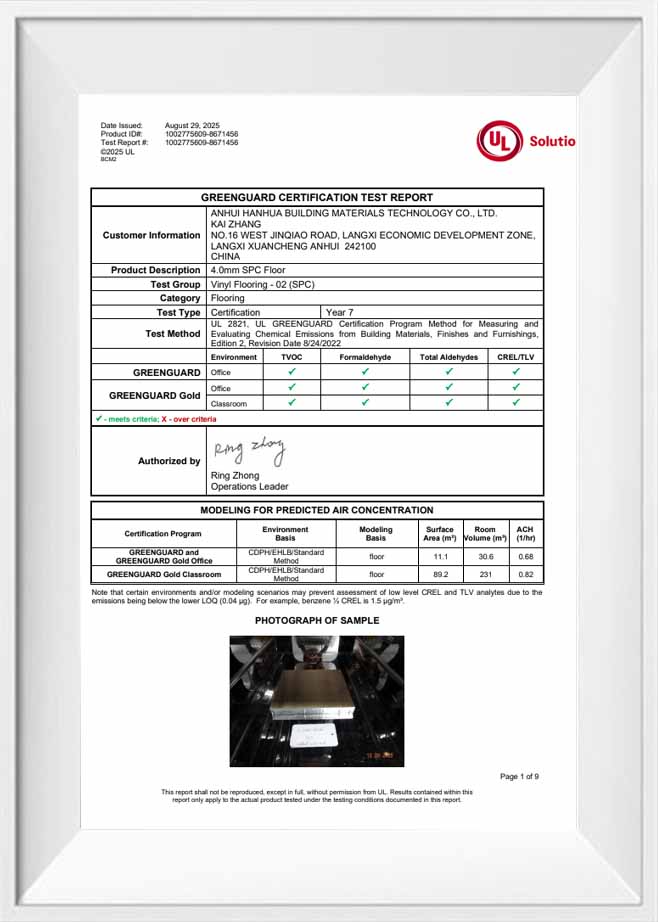

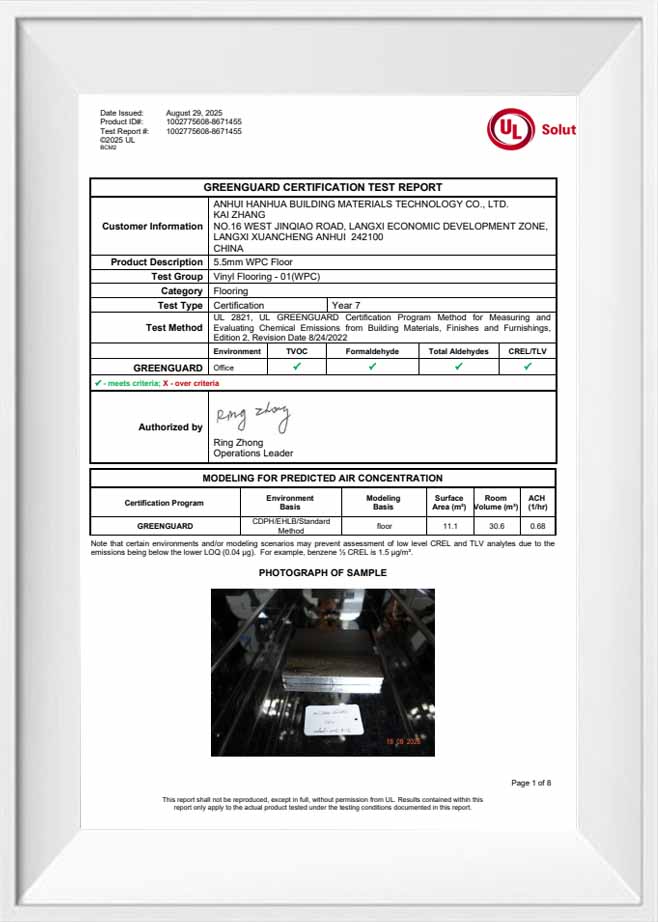

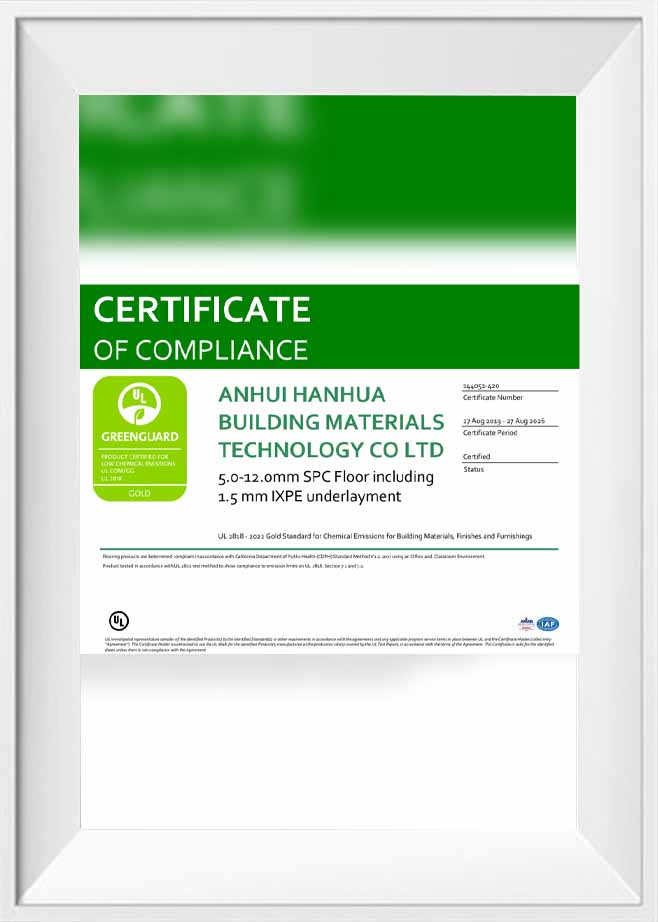

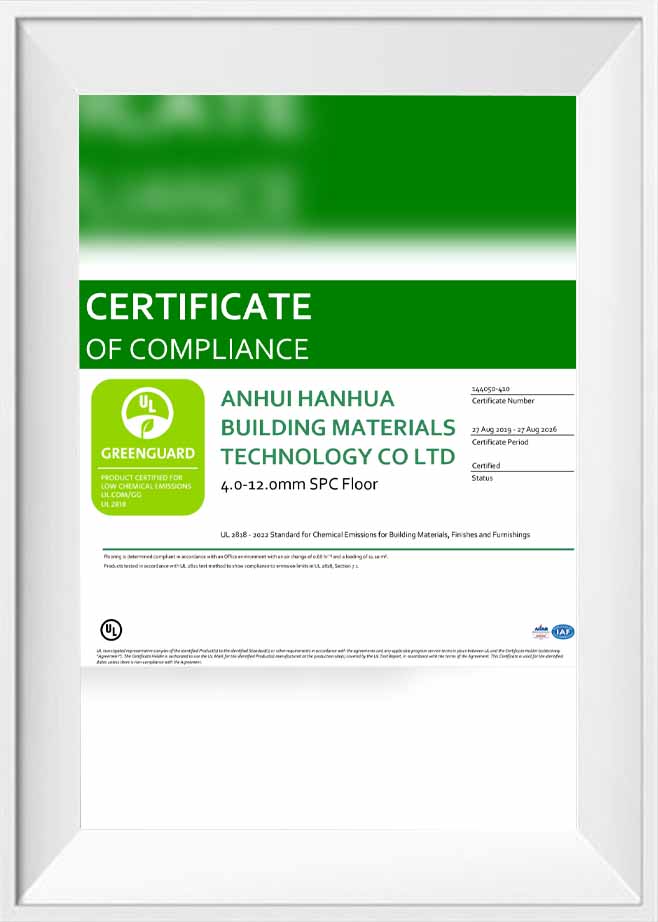

| GREENGUARD / GREENGUARD Gold | Low chemical emissions; GREENGUARD Gold has stricter limits for sensitive populations | Extensive VOC panel, formaldehyde, and semi-volatile compound tests | Preferred for child care, medical and educational facilities when choosing Flooring Accessories. |

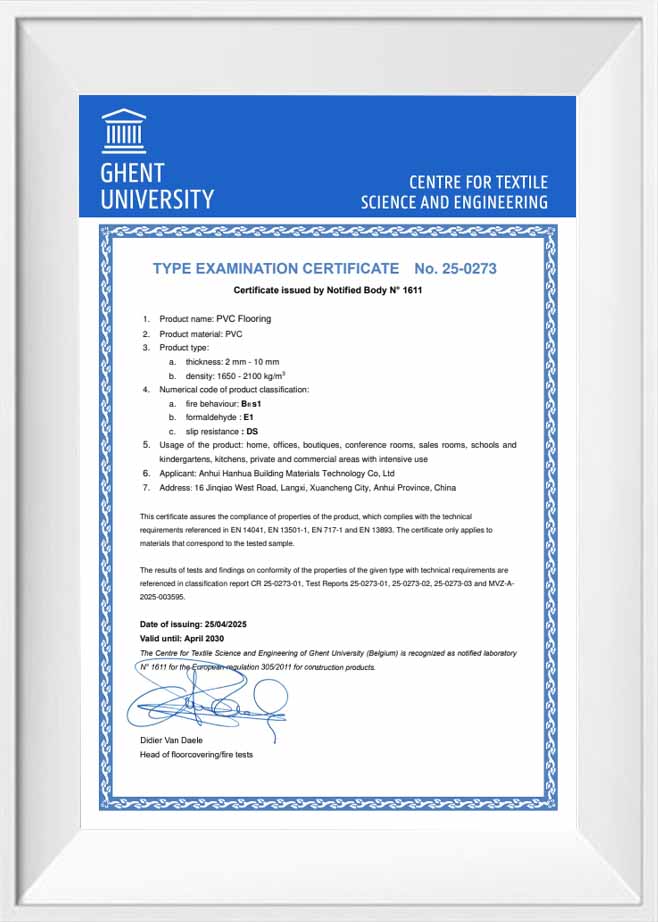

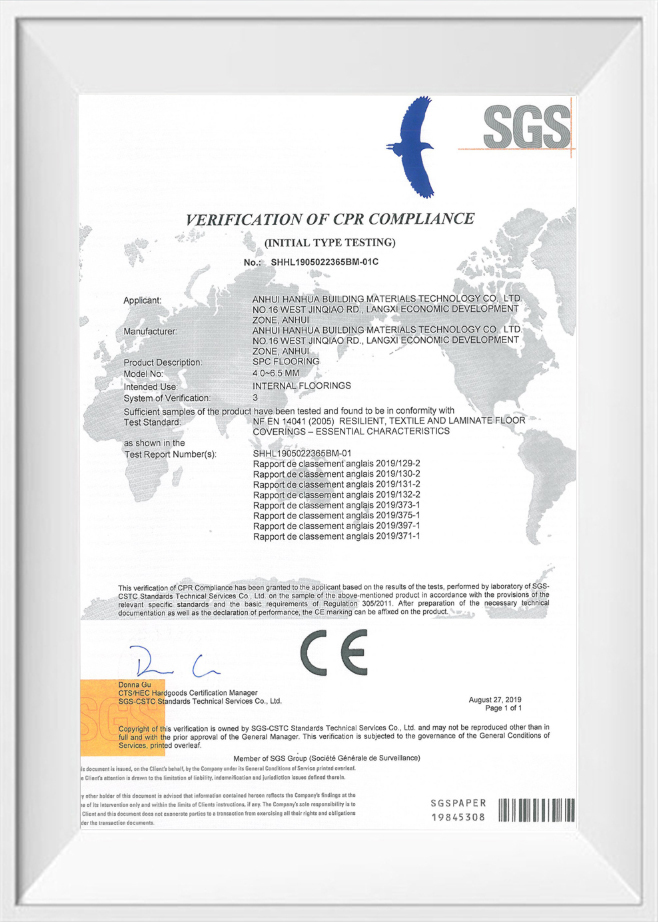

| CE Mark (related standards) | Conformity with EU safety/environmental directives | Depends on product family: reaction to fire, formaldehyde class, mechanical safety | Useful when exporting Flooring Accessories to EU markets; supports fire and chemical compliance. |

Practical Selection Criteria for Healthier Indoor Environments

Material composition and surface treatments

Select accessories whose base materials (PVC, aluminum, oak, engineered wood, or composite) and surface finishes (powder coat, lacquer, anodize) are documented to meet low-emission test results. For example, powder-coated metal trims generally have lower VOC emissions than solvent-based painted trims; likewise, engineered wooden skirtings with water-based finishes typically test better than those finished with solvent lacquers.

Adhesives, sealants and gasketing

- Specify adhesives with published FloorScore or GREENGUARD results when bonding or fixing Flooring Accessories; contact-grade adhesives can add VOC load if not certified.

- For edge seals and joint fillers use water-based, low-odor compounds and choose curing systems rated for low residual emissions.

- When selecting pre-assembled accessory strips, request material safety data sheets (MSDS) and emission test reports to compare long-term off-gassing profiles.

Installation and Post-Installation Measures That Reduce Risk

Even certified Flooring Accessories can contribute to indoor concentrations if installed in poorly ventilated spaces or applied with non-compliant adhesives. Adopt these practical steps on site:

- Ventilate during and after installation — cross-ventilation and temporary mechanical ventilation reduce peak VOCs from adhesives and finishes.

- Allow for initial off-gassing period before occupying the space; follow manufacturer’s recommended cure times for adhesives and coatings.

- Avoid mixing uncertified accessory products with certified flooring in sensitive projects—documented system performance matters more than individual pieces.

Maintenance, Cleaning and Lifetime Performance

Maintenance choices affect long-term indoor air quality. Abrasive cleaning, frequent re-coating, or use of solvent-based polishes on Flooring Accessories can reintroduce harmful emissions. Prefer microfiber cleaning and pH-neutral detergents; where re-finishing is required, choose water-based sealers and plan for adequate ventilation during application.

Specifying for Different Project Types

Residential remodels

Recommend certified accessories for bedrooms and living areas when occupants include children, elderly or allergy sufferers. Provide homeowners with simple checklists: certification label, MSDS, and recommended curing/ventilation steps.

Commercial and institutional projects

For schools, hospitals, and open-plan offices prioritize GREENGUARD Gold or equivalent. Require manufacturers to provide third-party test reports for both the accessory and any adhesives or installation materials used in conjunction with Flooring Accessories.

Checklist for Procurement Teams

- Request third-party emission certificates (FloorScore, GREENGUARD) and confirm scope covers the exact accessory model.

- Obtain product composition details and finishing process descriptions to assess potential hidden emissions.

- Specify acceptable adhesives and installation materials in the contract; reject on-site substitutions that lack certification.

- Plan for post-installation air monitoring in sensitive projects—simple VOC spot checks can verify compliance with project thresholds.

Adopting certified Flooring Accessories and compatible installation materials is a pragmatic way to protect indoor air quality without sacrificing design. Certification data, clear procurement rules, and on-site practices together ensure accessory choices support healthier, longer-lasting interiors.

English

English Español

Español Deutsch

Deutsch