Thermal Performance Considerations for Fast-Installation Wall Panel

Fast-installation wall panels often incorporate composite structures that influence indoor thermal stability. Beyond simple insulation values, factors such as heat-transfer pathways, the density of core materials, and surface reflectivity determine overall performance. For example, MGO-based decorative panels paired with insulated foam layers can reduce thermal bridging, while darker surface finishes may increase heat absorption in sun-exposed rooms. When planning usage in climates with extreme temperature differences, contractors should evaluate how panel thickness, joint design, and accessory trims affect seasonal energy demand.

Comparative Thermal Behavior

| Panel Structure | Thermal Influence |

| Solid MGO Core | Stable temperature regulation; moderate insulation |

| MGO + PU Composite | Strong insulation; reduced energy loss |

| PVC Decorative Shell + Hollow Layer | Lightweight; performance depends on cavity treatment |

Moisture-Management Strategies in Decorative Wall Panel Systems

Decorative panels often act as the visible surface layer but may also influence moisture control when installed in humid environments. When selecting panels for kitchens, basements, or coastal regions, the vapor permeability of the core material and the sealing performance of the joint system matter as much as the waterproof rating of the surface finish. MGO boards, for example, exhibit strong moisture resistance and dimensional stability, reducing warping risks compared with organic-fiber materials.

Key Moisture-Control Methods

- Use edge-sealed panel designs to minimize moisture infiltration points.

- Incorporate breathable underlayment to allow controlled vapor diffusion.

- Select hydrophobic surface treatments to enhance durability in wet areas.

Acoustic Optimization Techniques for Interior Wall Panels

While decorative wall panels are often chosen for visual effect, many engineered panels also influence acoustic comfort. Panels with porous backings, micro-perforated surfaces, or layered structures can significantly reduce echo and improve speech clarity. In commercial spaces such as cafés and classrooms, combining fast-installation panels with acoustic underlayers allows rapid transformation of sound environments without structural modification.

Acoustic Enhancement Approaches

- Use staggered panel arrangements to scatter reflective sound paths.

- Choose panels with felt or fiber-backed structures for absorption.

- Integrate air-gaps behind rigid boards to boost low-frequency damping.

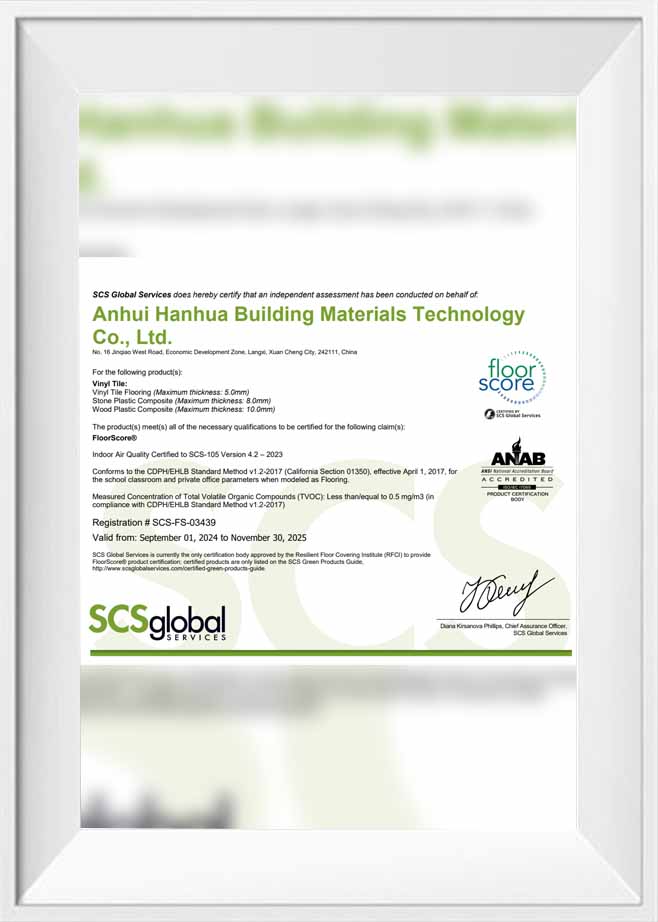

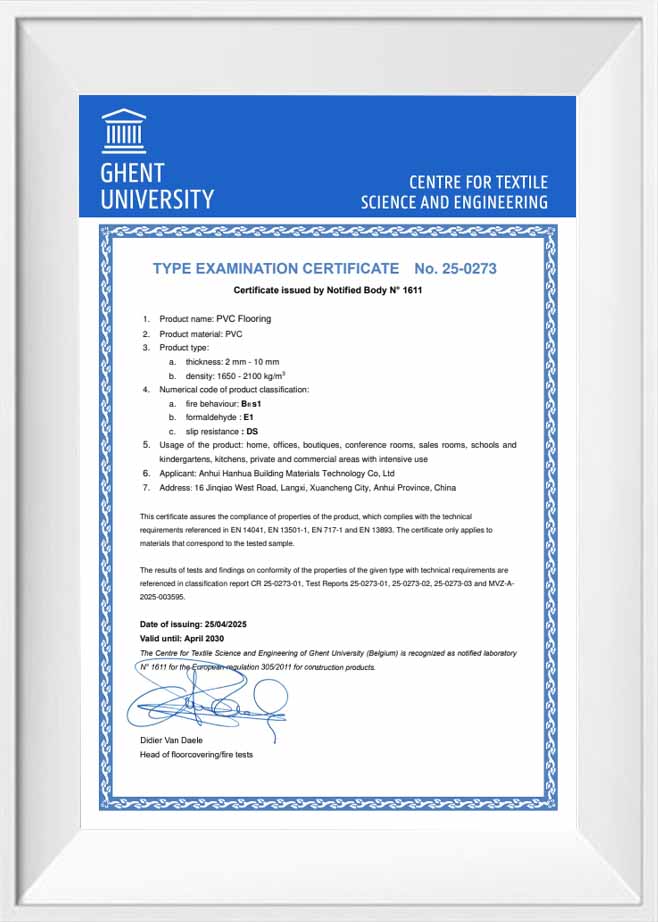

Fire-Safety Enhancements in Modern Wall Panel Materials

Eco-friendly MGO boards are known for their superior fire resistance, but system-level safety also depends on installation details and accessory materials. Adhesives, corner trims, and joint fillers should be evaluated for flame-spread behavior, especially in commercial buildings where codes require consistent performance across all components. Panels used in vertical escape routes or public corridors often use non-combustible substrates paired with decorative PVC surfaces that have controlled smoke production.

Fire-Related Considerations

- Verify compatibility between panels and fire-rated adhesives.

- Ensure panel systems maintain integrity under prolonged heat exposure.

- Consider smoke toxicity when selecting decorative film layers.

Factory-Integrated Surface Treatments for Long-Term Aesthetic Performance

Decorative wall panels from large-scale manufacturers often feature pre-applied surface technologies that enhance durability. UV-cured coatings, scratch-resistant films, and anti-stain layers minimize maintenance needs in high-traffic environments. For PVC and MGO composite panels, surface laminates printed with high-precision digital textures replicate wood, stone, and textile patterns with long-lasting clarity, ensuring visual consistency even after years of exposure.

Common Factory-Applied Enhancements

| Treatment Type | Primary Benefit |

| UV Protective Coating | Prevents discoloration in sunlit areas |

| Textured Laminate Film | Enhances tactile realism and scratch resistance |

| Anti-Stain Surface Layer | Facilitates easier cleaning in kitchens and hallways |

Installation Error Prevention for Fast-Installation Panel Systems

Although fast-installation wall panels simplify construction, improper alignment, insufficient substrate preparation, or using the wrong fasteners can compromise long-term performance. Panels designed with snap-lock or tongue-and-groove structures require precise angle insertion to prevent stress points. In large wall expanses, expansion gaps should also be considered—especially for PVC-based materials susceptible to thermal movement.

Frequent Installation Issues & Solutions

- Issue: Misalignment along vertical seams.

Solution: Use laser guides and insert panels with consistent pressure. - Issue: Substrate unevenness causing gaps.

Solution: Employ level-compound smoothing before panel installation. - Issue: Over-tightened screws leading to cracking.

Solution: Use torque-controlled drivers and compatible fasteners.

English

English Español

Español Deutsch

Deutsch