Advanced Acoustic Optimization with SPC Rigid Core Flooring

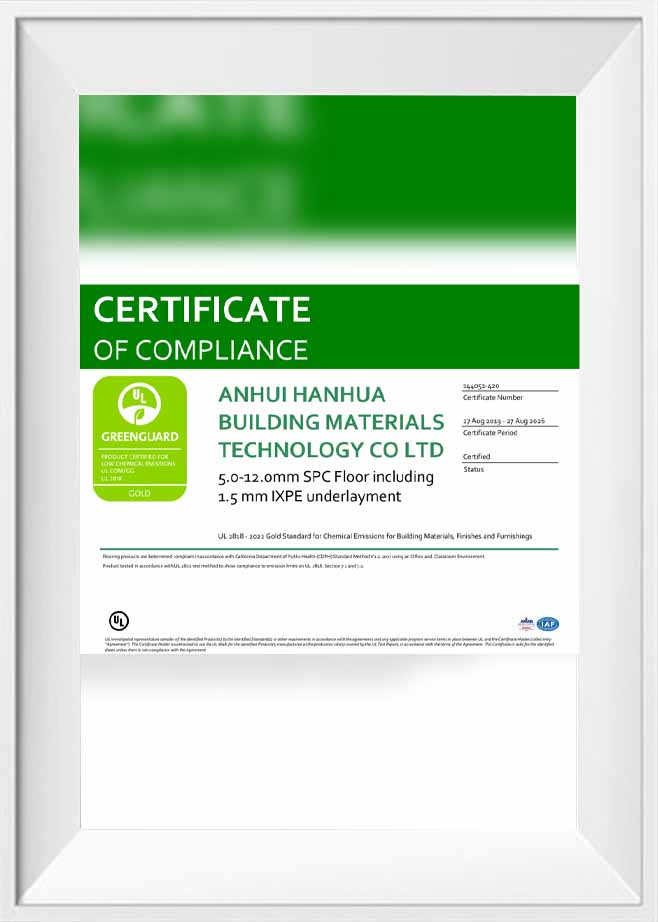

SPC rigid core flooring is often selected for commercial and residential projects needing improved acoustic performance, but the effectiveness depends heavily on pairing the core with the right underlayment system. While IXPE and EVA foams are widely used, high-density cork or rubber composites offer superior low-frequency noise absorption, which is crucial in multi-story buildings or open-plan layouts. For projects in the EU or Australia that must satisfy stricter acoustic regulations, combining an SPC rigid core with a 1.5–2mm high-density acoustic layer can significantly enhance impact sound reduction without compromising floor stability.

Comparison of Acoustic Underlayment Options

| Underlayment Type | Low-Frequency Control | Durability | Typical Use Case |

| IXPE Foam | Moderate | High | Residential apartments |

| EVA Foam | Moderate | Medium | Retail spaces |

| Cork Layer | High | High | Eco-focused projects |

| Rubber Composite | Very High | Very High | High-traffic commercial buildings |

Dimensional Stability Challenges in Extreme Climates

SPC rigid core flooring offers strong dimensional stability, but extreme environments—such as desert climates, cold Nordic regions, or humid coastal areas—can still impact long-term performance. Differences in indoor temperature swings caused by HVAC cycles or underfloor heating may create micro-expansions within the core. To mitigate this, professional installers in the US and EU use perimeter expansion gaps larger than standard specifications or select SPC boards with engineered mineral composites that maintain stability under rapid thermal fluctuations.

Installation Precautions for Climate-Exposed Projects

- Increase expansion gaps from the typical 8mm to 10–12mm in regions with large temperature variations.

- Use transition profiles between rooms to allow additional movement control.

- Condition the SPC boards indoors for at least 48 hours prior to installation.

- Avoid direct sunlight exposure during installation, which can temporarily deform the boards.

Surface Technology Innovations Beyond Standard Wear Layers

Modern SPC flooring manufacturers are moving beyond traditional UV coatings to adopt enhanced surface technologies that improve scratch resistance, stain protection, and visual realism. For high-end markets like Germany and France, customers increasingly prefer embossed-in-register (EIR) finishes, which synchronize the texture with the printed design layer. Some factories also apply ceramic bead reinforcement or anti-bacterial coatings to meet the durability and hygiene expectations of health-related commercial environments.

Key Surface Enhancements

- Ceramic bead coatings that significantly reduce micro-scratches from furniture movement.

- Anti-slip treatments designed for wet-prone spaces such as kitchens or entryways.

- Matte-finish UV layers that mimic natural hardwood aesthetics without reflective shine.

- EIR embossing for high-end realism, especially popular in EU market segments.

Evaluating Click-Lock Systems for Heavy Commercial Use

Although most SPC flooring uses a click-lock mechanism, not all locking systems perform equally under heavy commercial loads. In warehouse offices, schools, or high-traffic retail stores, the stress on the joint system increases dramatically. International buyers often compare the precision of click-lock machining, the pressure tolerance of the locking angle, and the thickness of the core material. High-density SPC cores with precision-milled lock profiles typically resist separation better when large rolling loads—such as carts or movable shelves—are involved.

Signs of High-Quality Click-Lock Engineering

- Tight interlocking tolerance with minimal visible seams.

- Locking angle engineered to balance ease of installation and joint strength.

- High-density core (≥1900 kg/m³) to prevent crushing of joint edges under load.

- Smooth engagement without chipping or splintering at the lock edges.

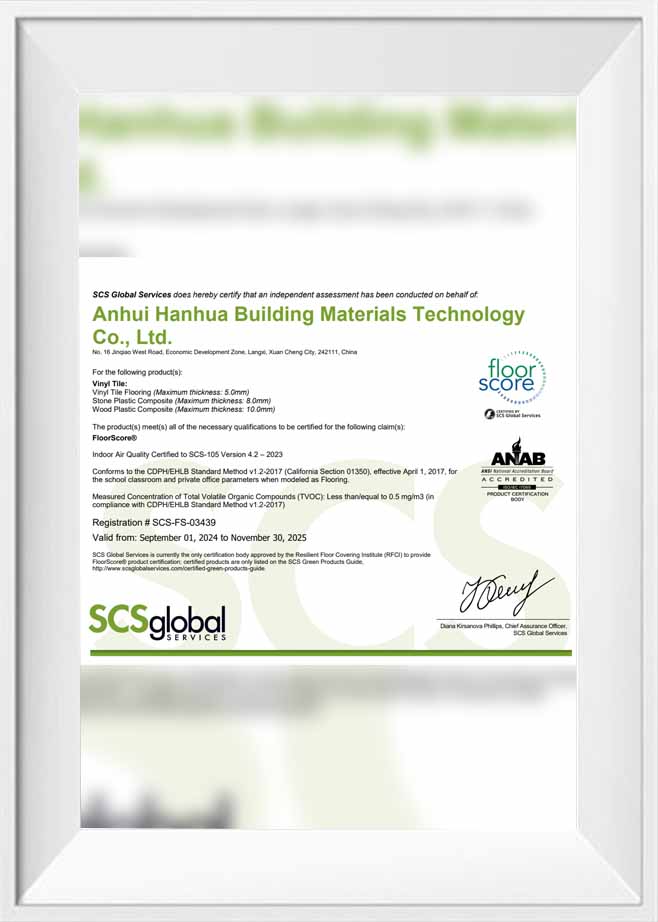

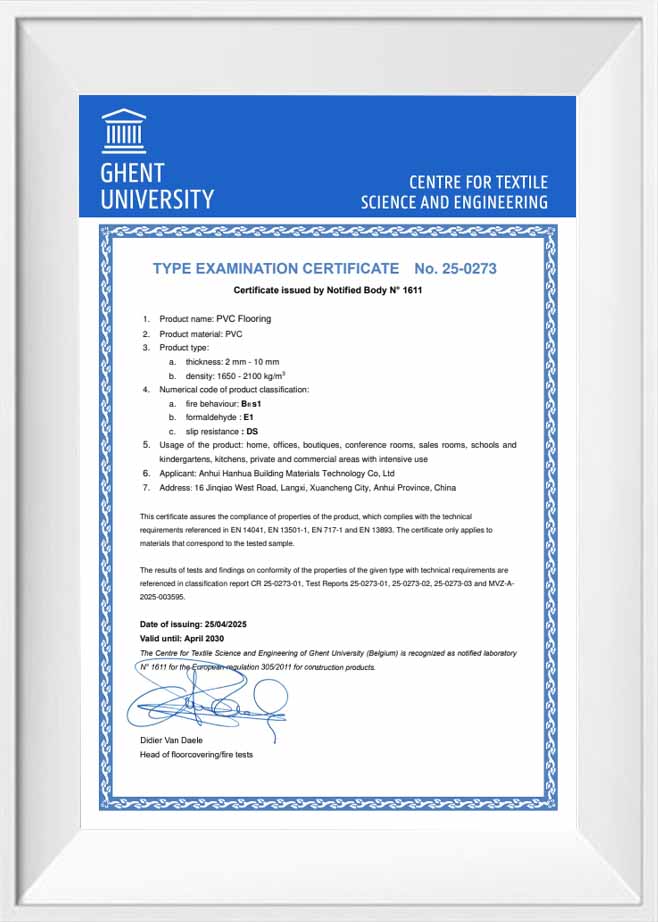

Sustainable Material Trends in SPC Rigid Core Flooring

The sustainability focus in SPC flooring has shifted beyond basic virgin or recycled PVC ratios. European importers, in particular, now evaluate the carbon footprint of the entire manufacturing cycle—covering extraction, production, transportation, and end-of-life recyclability. Many suppliers have started adopting non-phthalate plasticizers and implementing closed-loop recycling systems to repurpose trimming waste. The shift toward magnesium oxide (MGO) substrates combined with SPC layers is also gaining attention due to improved fire resistance and reduced reliance on pure plastic-based cores.

Eco-Related Considerations for International Buyers

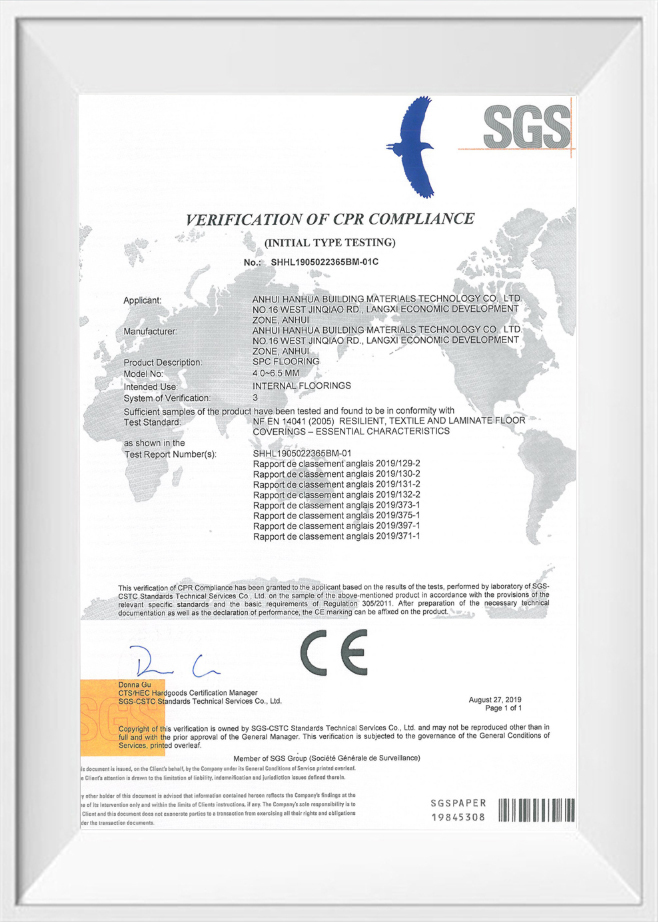

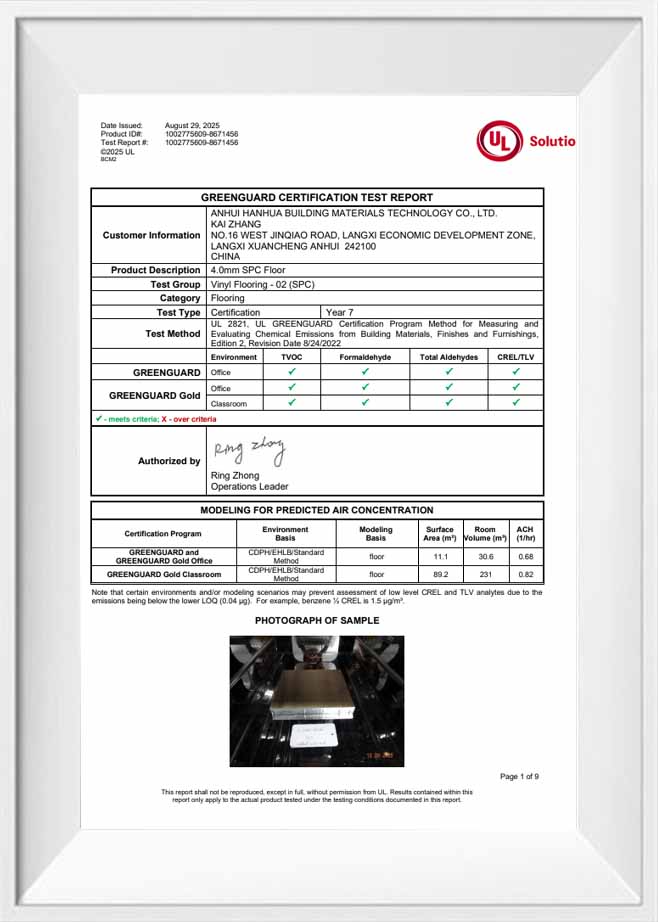

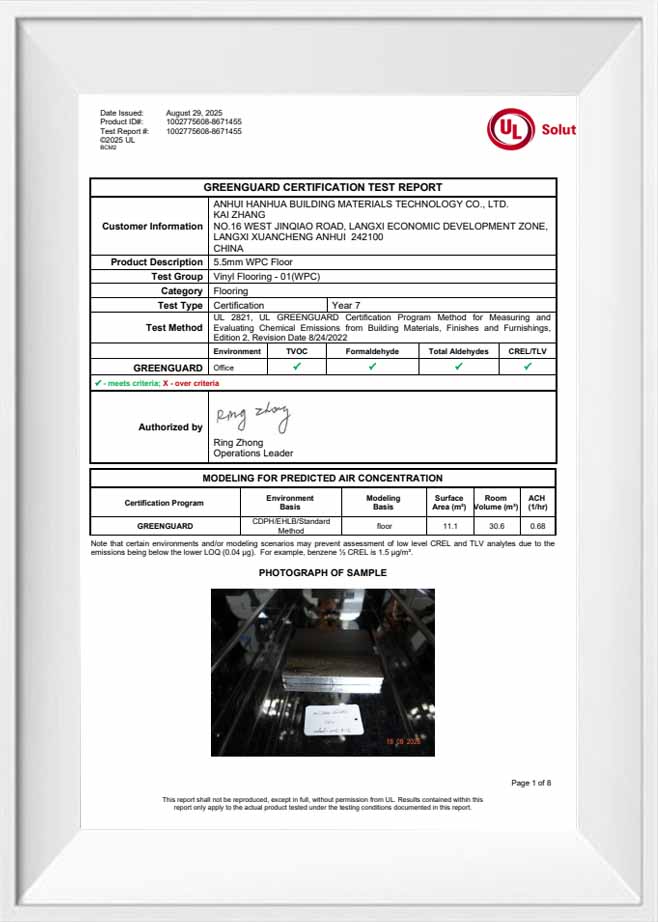

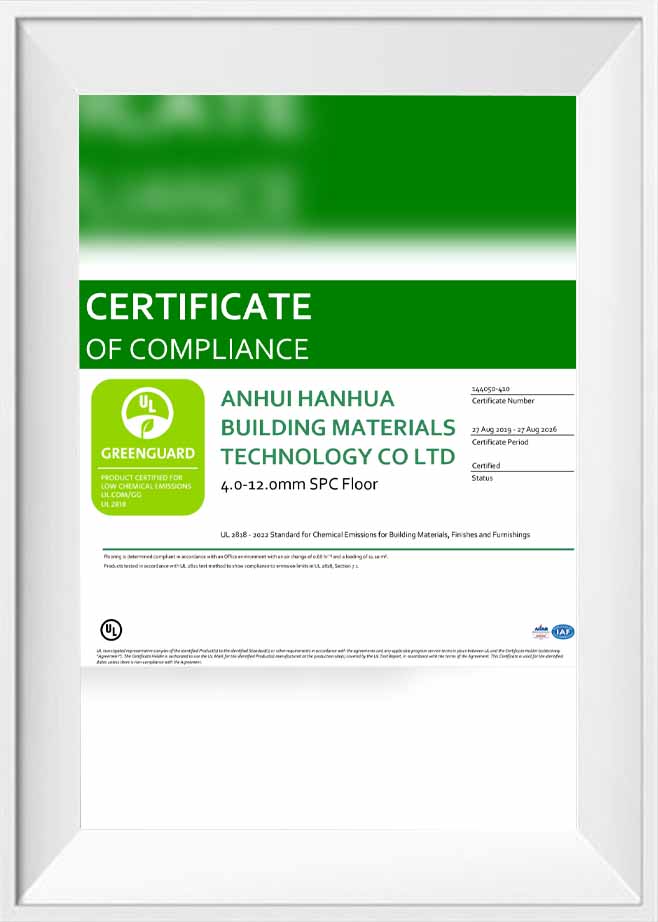

- Request emission certifications such as FloorScore or EN 16516 for compliance in the US and EU.

- Assess the proportion of recycled PVC content and whether it affects product stability.

- Consider suppliers with energy-efficient production lines to reduce carbon impact.

- Evaluate long-term recyclability, especially for large-scale renovation projects.

English

English Español

Español Deutsch

Deutsch