Material design: how permanent conductive formulation maintains long-term conductivity

Choose Conductive Floor Tiles produced by homogenized compression of PVC resin, calcium carbonate and conductive additives to achieve a continuous conductive matrix through the entire thickness. This avoids a conductive coating layer that can wear off; conductivity comes from the bulk material so conductivity paths persist after surface abrasion. Pay attention to additive dispersion during manufacture — uneven dispersion creates local insulating zones that break continuity under mechanical stress.

Grounding strategy and layout planning for static-sensitive production spaces

Design the flooring layout as part of a site-wide grounding network. Connect conductive flooring to a dedicated grounding bus at regular intervals so stray charge flows to a common reference. Place grounding points near equipment racks, dock doors and operator stations. Use copper strips or conductive adhesives at floor-to-wall and floor-to-equipment interfaces to preserve low-impedance paths.

Seam and joint treatment: keeping conductivity across panels and tiles

Seams are the weakest link for conductive continuity. Use heat-welded seams or conductive welding rods that fuse tiles into a continuous surface. Where welding is impractical, install conductive tape beneath seams and overlap by at least 20 mm. For removable tiles, design interlocking conductive contacts that maintain low resistance when panels meet.

Cleaning and chemical compatibility that preserve conductive performance

Select cleaning agents that do not leave insulating residues or attack conductive additives. Avoid solvent-based strippers that extract plasticizers or additives; choose pH-neutral detergents validated for conductive PVC. Adopt cleaning schedules tied to production intensity: high-throughput production zones require daily light cleaning and weekly deep cleaning to avoid particulate build-up that degrades surface contact.

Interaction with footwear, seating and mobile equipment

Consider how operators, carts and chairs interact with the floor. Pair conductive flooring with ESD footwear or heel straps designed to provide controlled resistance to ground; uncontrolled low-resistance footwear can create localized current paths that trip protection or damage sensitive devices. Fit caster wheels and chair bases with conductive or dissipative wheels; test rolling contact resistance under expected loads to confirm continuous performance.

Environmental effects: humidity, temperature and particulate influence

Ambient conditions change surface resistivity. Higher humidity lowers resistivity and can improve charge dissipation, while very low humidity raises resistivity and increases electrostatic risk. Control HVAC to keep relative humidity within a target range aligned with the process sensitivity. Implement particle-control measures (filtration, sticky mats at entrances) because particulate layers form insulating films that interrupt conductive paths.

Inspection and testing: methods to verify continuous conductivity

Routine verification requires both spot checks and area measurements. Use point-to-point resistance meters to test welds, seams and grounding strips. Complement with surface resistivity mapping tools that scan larger areas to detect anomalies. Establish acceptance criteria for resistance-to-ground at production-critical locations and record trends to detect progressive degradation.

Common test methods and what they reveal

| Test | What it measures | When to use |

| Resistance-to-ground | Continuity from a point on floor to building ground | After installation, monthly in production areas |

| Surface resistivity mapping | Distributed resistivity across an area | Commissioning and periodic audits |

| Weld seam continuity check | Local resistance across seams or joints | After seam welding or repairs |

Installation best practices that maximize ESD performance

Control subfloor preparation: remove insulating coatings, level the substrate and apply a conductive primer where required to maintain a low-impedance contact. During tile placement, bond tiles with conductive adhesive strips that align with factory conductive paths. Leave access panels for grounding point inspection and document grounding conductor routes in the as-built drawings.

Repair, retrofit and lifecycle considerations

For localized damage, cut out the affected tile and replace with a matched conductive tile welded into the surrounding floor. When retrofitting non-conductive floors, consider a conductive overlay system or install conductive mats permanently anchored and bonded to ground. Track cumulative wear and schedule full replacement when periodic resistivity mapping shows frequent out-of-spec areas.

Operational workflows that reduce electrostatic incidents

- Define ESD workstations with flooring, wrist straps and footwear as a system and require verification before processing sensitive components.

- Log daily quick-check resistance-to-ground measurements at critical locations; escalate if values drift beyond set thresholds.

- Train maintenance personnel to recognize conductive flooring damage signs (discoloration, delamination, seam gaps) and to perform basic continuity repairs.

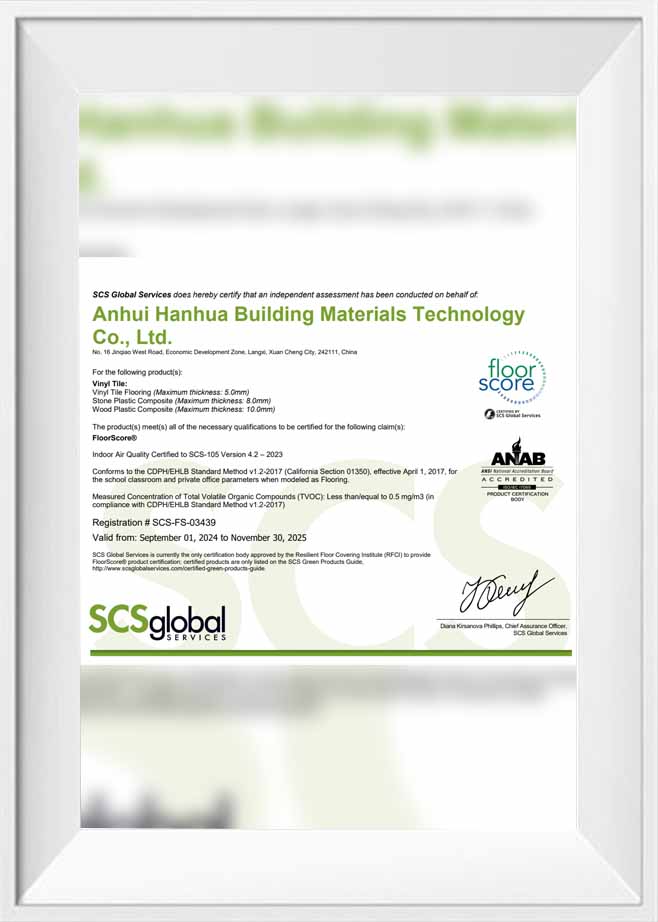

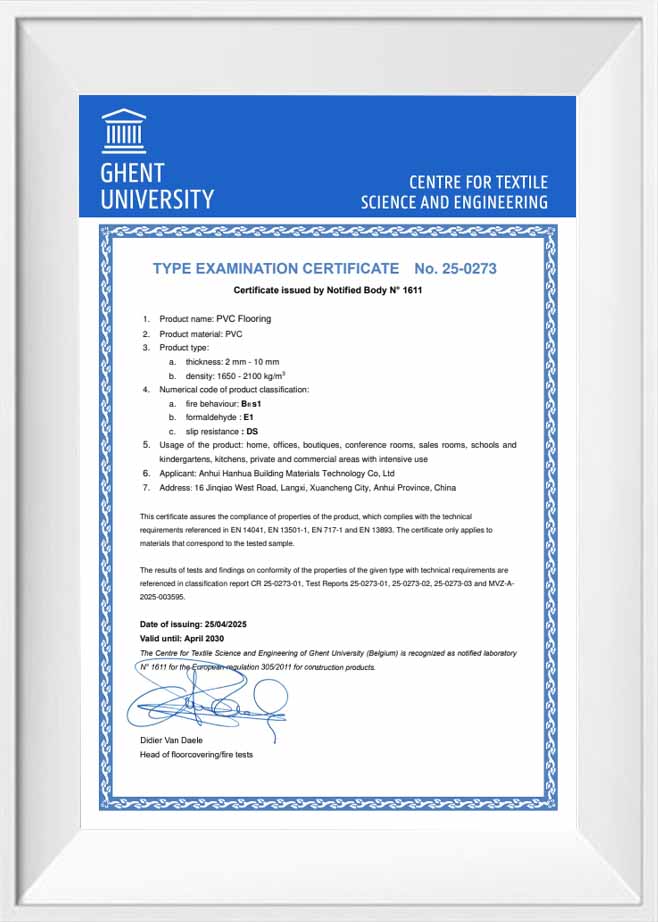

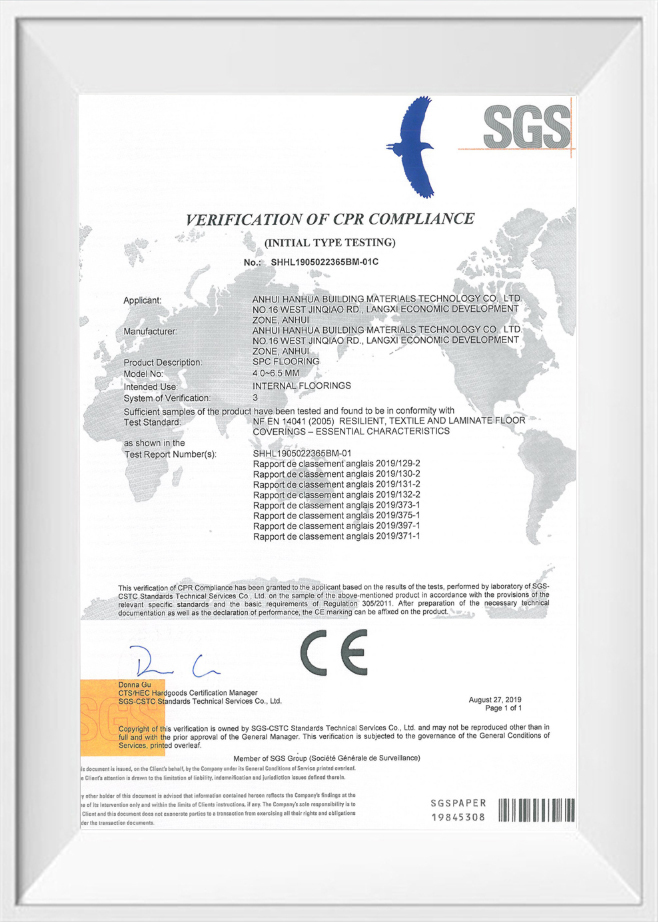

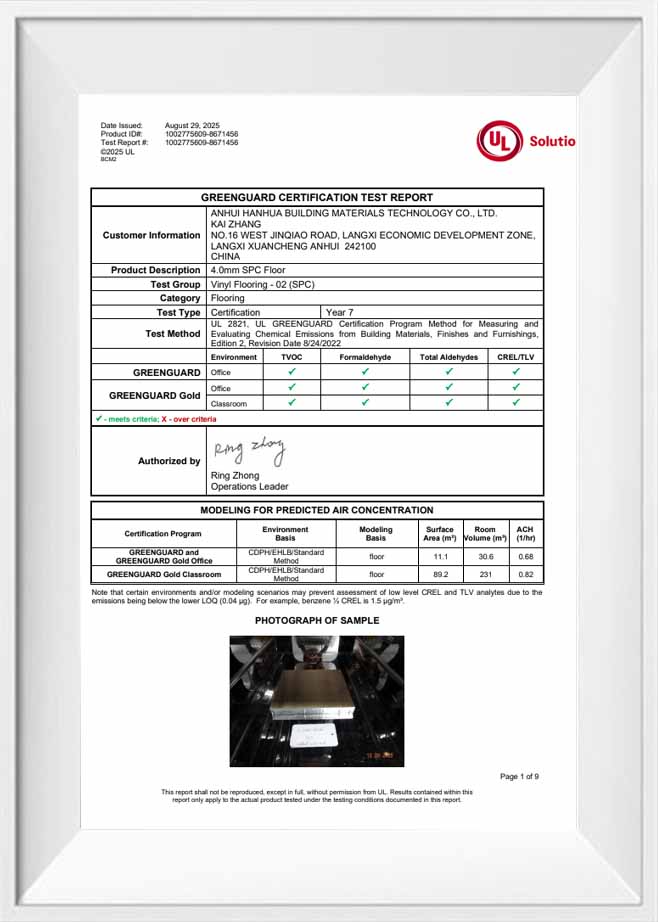

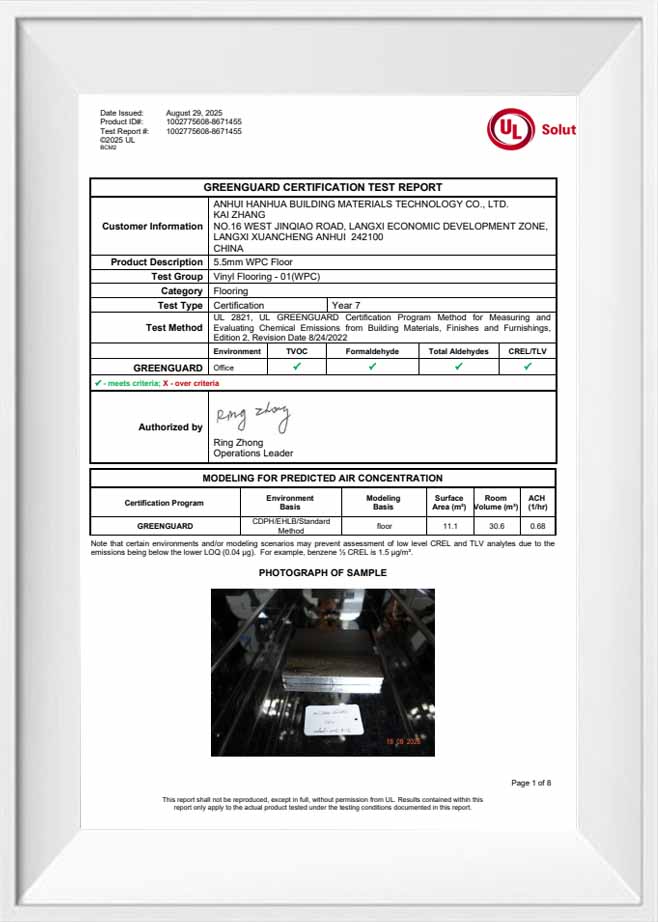

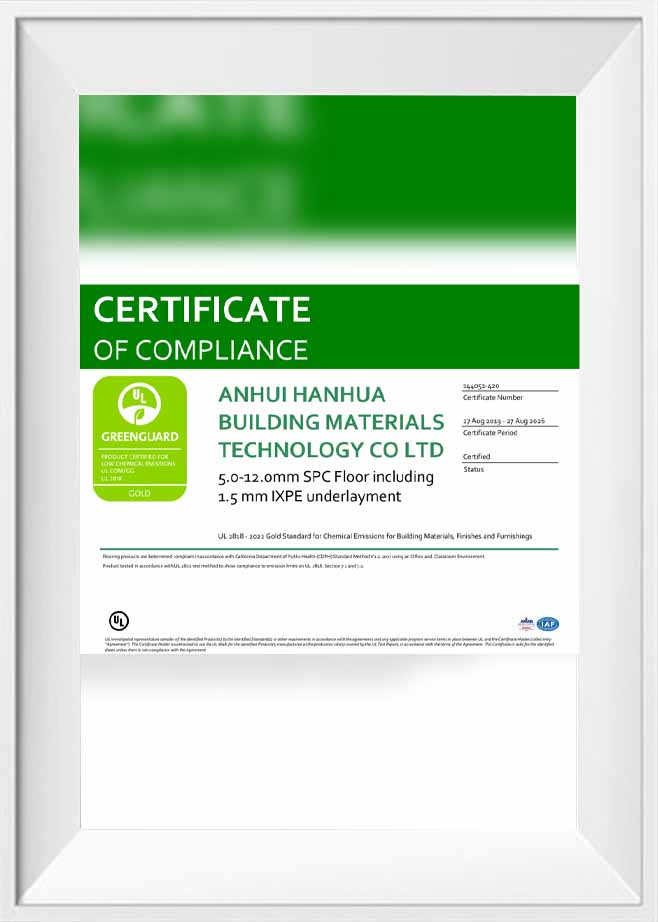

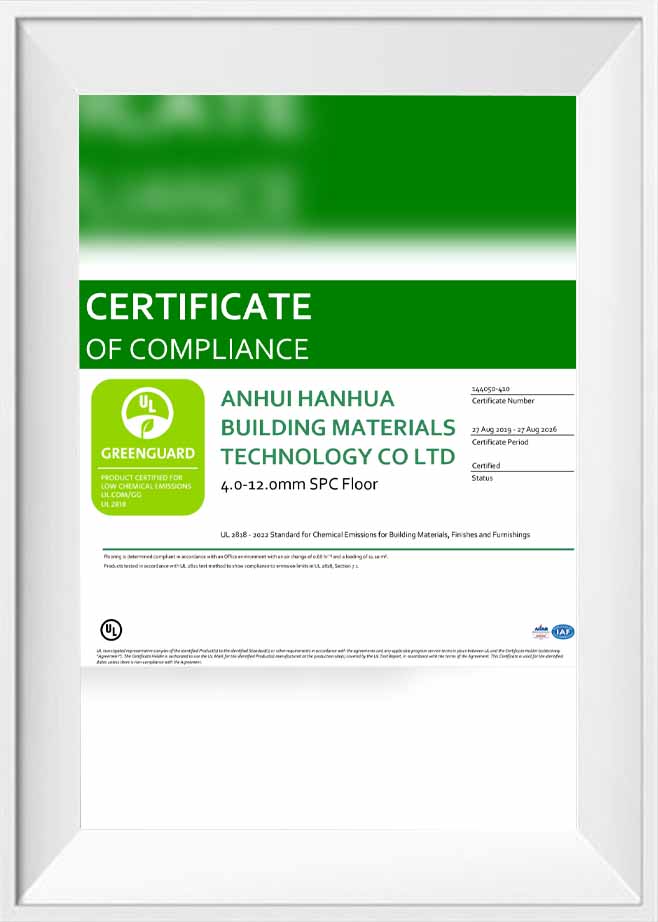

Product certification and export-grade quality considerations

Select Conductive Floor Tiles with recognized certifications for indoor air quality and product safety to meet client and regulatory requirements in target markets. For international projects, match certification documents to customer country requirements and include test reports that show long-term conductivity retention after accelerated wear tests.

English

English Español

Español Deutsch

Deutsch